Choosing the Right Casters and Wheels for Industrial Applications

Key Takeaways

- Optimal caster and wheel choices increase workplace efficiency and safety, and reduce downtime.

- Understanding load capacity, floor types, and mobility requirements is critical for performance.

- Wheel material, environment, and maintenance all influence caster longevity.

- Industry standards and emerging tech trends are shaping how facilities select mobility solutions.

- Regular upkeep and informed decisions can significantly lower long-term costs and risks.

Why Caster and Wheel Selection Matters in Industry

In today’s highly dynamic industrial sectors, casters and wheels are more than just accessories—they are essential to the seamless movement of raw materials, equipment, and finished products. Facilities often move thousands of pounds daily. Selecting inappropriate wheels increases operator effort and can result in equipment malfunctions, unnecessary product damage, or even safety violations. According to recent studies on industrial safety and efficiency, industrial ergonomics directly impacts productivity and employee well-being, especially in sectors that rely on frequent material handling.

The right choice of caster—such as those found among Blickle casters—can transform workplace movement from a physically taxing process to one that feels effortless and dependable, even under demanding workloads. Industries from logistics to manufacturing and healthcare depend on reliable casters to maintain smooth operations and avoid costly interruptions. A careful evaluation ensures your mobility solutions match your workflow and safety requirements, demonstrating a proactive approach to modern workplace challenges.

Factors to Consider When Selecting Casters

- Load Capacity: Smart caster selection begins with accurately estimating the total potential load. Factoring in unexpected overload scenarios, such as heavier shipments or equipment upgrades, guides buyers towards casters designed to handle stress without failure, minimizing operational risk.

- Floor Conditions: Not all surfaces are the same. Rough concrete, expansion joints, debris, and constant vibration require durable wheels, whereas polished concrete or tile floors prioritize noise reduction and floor protection. Matching wheels to the environment helps prevent marks, scuffing, or structural flooring damage over time.

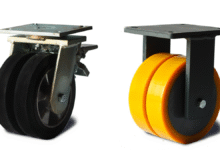

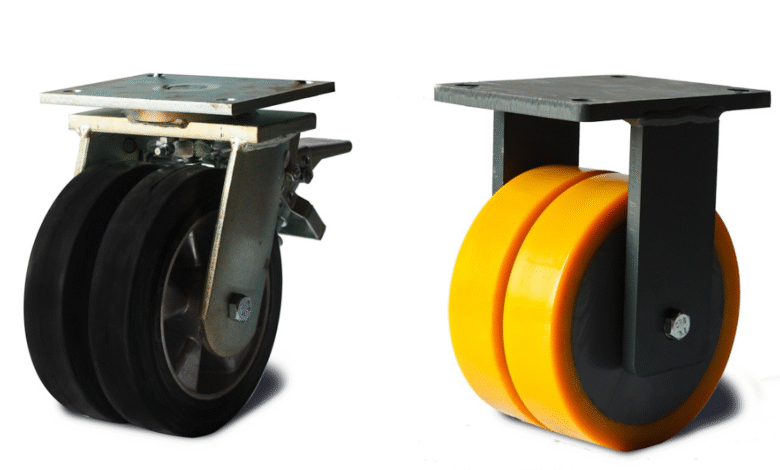

- Mobility Needs: Workplaces often face tight aisles or obstacles where maneuverability matters. Swivel casters are ideal for steering around corners, while rigid casters support stability and controlled straight-line rolling, especially on utility carts or conveyor lines.

- Environment: Hot, cold, wet, oily, or food-safe environments call for casters with specialized coatings, materials, or seals. Depending on industry needs, custom solutions can prevent everything from corrosion to microbial contamination.

Noise and ergonomic considerations are becoming increasingly relevant as businesses adapt to open workspaces and customer-facing logistics. Certain casters’ sound-dampening properties can dramatically improve comfort for both workers and customers, fostering a friendlier and more productive on-site atmosphere.

Standard Wheel Types and Their Benefits

Every industrial environment imposes unique demands on mobility hardware, and choosing the correct wheel type is essential for efficiency and cost savings. Polyurethane wheels, for example, are prized for their quiet rolls and ability to protect floors from scratches. They also resist oils, greases, and solvents, making them suitable for laboratories, hospitals, and modern offices where noise reduction is a bonus.

- Polyurethane: Reduces rolling resistance and absorbs minor shocks, offering a smooth ride over slightly uneven surfaces and providing less maintenance in sensitive environments.

- Rubber suppresses vibration and transmits less impact to transported items, which is particularly helpful when handling delicate equipment or traversing outdoor terrain and ramps.

- Steel/Cast Iron: Enables hauling the heaviest machinery without deformation. Though robust, these wheels are noisier and best paired with protective flooring for indoor use.

- Thermoplastic: Lightweight, maneuverable, non-marking, and resistant to chemical spills, ideal for industries with strict hygiene requirements.

Choosing the correct wheel ensures long-term performance and can minimize the frequency of floor repairs. Operations that cross thresholds or run over small obstacles should opt for larger wheel diameters to prevent abrupt stops and reduce worker fatigue.

How to Size Casters Properly

- Calculate Total Load: Add the heaviest load the cart or platform could bear to the equipment’s weight. Failure to account for both components is a common reason for premature caster failure.

- Load Per Caster: Divide the total weight by the number of casters and add a 33% safety margin. For a manual cart weighing 1,000 pounds and carrying 800 pounds of product, set your calculation at 1,800 pounds across four casters. Each caster should, therefore, safely support at least 600 pounds.

- Wheel Size Matters: Larger wheels travel more easily over cracks, extensions, and debris, while smaller wheels offer a lower deck height and a more stable load for level, smooth factory floors.

These calculations, while simple, are often overlooked during hasty purchases. Addressing sizing up front can ward off unexpected downtime and keep your people and products safe in motion.

Industry Standards and Guidelines

Safety and compliance have never been more critical. Companies that align with recommendations from organizations like the American National Standards Institute (ANSI) benefit from reduced risk of accidents, inspections, and worker compensation claims. ANSI guidelines offer structured recommendations, such as suggested minimum load ratings, noise levels, and wheel materials for specific applications.

Well-documented industry standards also assist procurement teams in comparing caster features, ensuring reliability and regulatory compliance, two key factors influencing insurance rates and audit results.

Environmental Considerations

Facilities face various environmental challenges, including exposure to corrosive agents, washdown procedures, and subzero storage. Stainless steel or coated caster frames maintain hygiene and resist rust, while polymer-based materials protect against bacteria and chemical damage. In sanitation-focused environments like food processing plants, the right caster selection supports performance and health code compliance. Sealed ball bearings ensure continuous mobility and extend service intervals, ensuring trouble-free mobility throughout demanding schedules.

Maintenance Tips for a Longer Lifespan

Regular maintenance of a vehicle’s axle and wheels involves removing debris, applying lubricant, inspecting wheels for signs of wear, and tightening bolts and mounting hardware. Regular maintenance helps prevent mechanical failures, maintains factory safety standards, and reduces unplanned downtime. High-use carts should be lubricated at least once every few months. Regular inspections and tightening of bolts and mounting hardware can prevent caster wobble, unexpected detachments, or misalignment, affecting vehicle tracking.

Recent Trends in Industrial Mobility

Automated guided vehicles and robotics transform material handling, leading businesses to adopt modular, easily reconfigurable caster systems. These systems are expected to accommodate sensors and data feedback, enabling operations to track movements, prevent overloads, and schedule predictive maintenance. These future-ready caster systems can adapt to new layouts, helping companies thrive as markets shift and technologies advance.

Final Thoughts

Selecting the right caster and wheel is crucial for a competitive edge in efficiency, safety, and operational flexibility. Understanding your business’s unique requirements, including load, environment, standards, and future growth, ensures a smoother, safer, and more productive facility. Utilizing industry standards and product specifications ensures choices can withstand daily demands and future innovations. Investing in research and maintenance can provide years of reliable, worry-free mobility for any industrial operation.