Forrest Gump 2: The Sequel We Never Knew We Needed

Explore the untold story of Forrest Gump 2, its potential, rumored plotlines, and why fans still hold hope. A deep dive into everything about the long-awaited sequel.

The Legacy of Forrest Gump

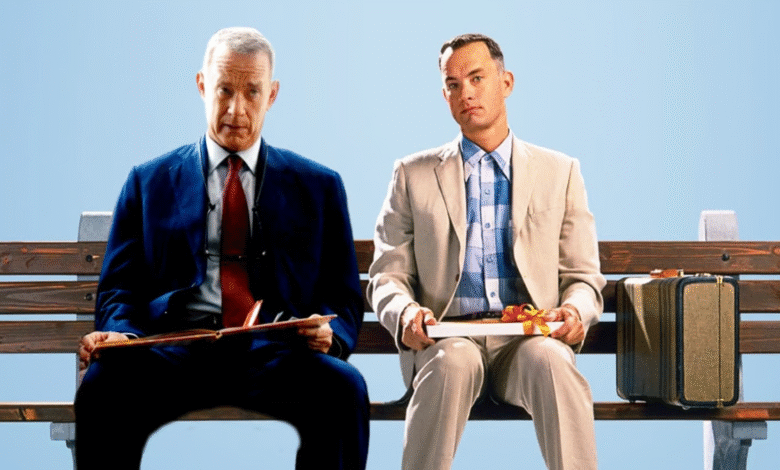

Forrest Gump isn’t just another classic movie. It’s a piece of cinematic history. Released in the mid-90s, the film captured the hearts of millions around the world. The story of Forrest’s simple yet impactful journey through decades of American history is nothing short of extraordinary. Played by Tom Hanks, Forrest wasn’t the kind of character you easily forget. His catchphrases, quirks, and that bench scene made an imprint on pop culture that refuses to fade.

When a movie like Forrest Gump makes such a mark, it’s only natural that people start asking, “What if there was a sequel?” That question has lingered for years. With discussions, rumors, and wishful thinking floating across fan forums, social media, and even Hollywood boardrooms, the dream of Forrest Gump 2 remains alive.

The original film ended on a hopeful yet slightly melancholic note. Forrest watches his son board the school bus, clearly proud and full of love. It was a closure, but also a doorway to a potential new story. What happened to Forrest Jr.? Did Forrest ever find new love? Did he ever run again? All these questions make the idea of a sequel even more tempting.

The Rumors and Possibilities Surrounding Forrest Gump 2

Over the years, several whispers and leaks have hinted at the development of Forrest Gump 2. Whether it was from interviews with cast members or vague statements from Paramount executives, these hints stirred fan excitement. Although no official movie ever materialized, the buzz around Forrest Gump 2 has never really died down.

One of the biggest drivers behind this sustained interest is the sheer love for the character. Forrest is someone people root for, and fans genuinely want to see what becomes of him in the next chapter of his life. Some of the rumored plotlines even involve Forrest Jr. growing up and taking on the modern world, mirroring his father’s charm and optimism in a very different America.

Another angle fans have explored is Forrest dealing with events from the late ’90s into the 2000s. Imagine Forrest unknowingly getting involved in the dot-com boom or accidentally sparking a viral moment before the internet even fully took off. The comedic and heartfelt possibilities are endless.

The Book Sequel: Gump and Co.

Interestingly enough, a sequel to the novel Forrest Gump already exists. Written by Winston Groom, Gump and Co. was published in the mid-90s and picks up where the original story left off. In this version, Forrest deals with raising his son, failing at business ventures, and even interacting with historical figures like Saddam Hussein.

The tone of the book is darker and more cynical compared to the original film. Groom seemed to channel more satire and less innocence in the follow-up. That might be one of the reasons Hollywood never went ahead with adapting Gump and Co.. It just didn’t have the same heart that made Forrest Gump so lovable. Still, it exists, and it gives fans a glimpse into what Forrest Gump 2 might have looked like if it followed the book.

Yet, not all fans are on board with this direction. Some believe the original film is perfect as it is and that a sequel might risk damaging its legacy. That’s a fair argument. Sequels often fall into the trap of trying to recapture lightning in a bottle. But if done with the right intention and creative team, Forrest Gump 2 could add meaningful depth to the character without losing the magic.

What Could a Modern Forrest Gump 2 Look Like?

Let’s get creative for a moment and picture what Forrest Gump 2 might actually look like in today’s world. Imagine Forrest living through Y2K, 9/11, the rise of social media, and even the COVID-19 pandemic. His naive charm would create hilarious and heartfelt moments as he stumbles through a technologically advanced and emotionally complex era.

Forrest Jr. could be a central figure in the story. Maybe he becomes a tech genius, or maybe he struggles with modern life, completely different from his dad’s approach. Either way, seeing Forrest as a father navigating modern parenting, education, and society would strike a relatable chord with audiences today.

You could also incorporate real-life events like the Obama presidency, the 2008 financial crisis, and the climate change movement. Forrest’s innocent perspective would bring new life and meaning to these pivotal moments in recent history. There’s even potential for a gentle exploration of mental health, veterans’ issues, or racial equality—all seen through the eyes of someone who never judges and always listens.

Tom Hanks and the Unlikelihood of a Sequel

If we’re being honest, one of the biggest hurdles in making Forrest Gump 2 is Tom Hanks himself. He has publicly stated multiple times that he has no interest in reprising the role. In interviews, he’s mentioned how the original film stands on its own and doesn’t need a follow-up. That’s a pretty clear message.

And let’s be real: Forrest without Tom Hanks is like peanut butter without jelly. It just wouldn’t work. His portrayal was so iconic that imagining anyone else in the role feels wrong. While studios have considered everything from reboots to spin-offs, nothing can quite match the magic of Hanks as Forrest.

Still, Hollywood has a way of reviving things when the timing feels right. Whether it’s through flashbacks, CGI, or even a limited series featuring Forrest Jr., the door isn’t completely closed. It would take a perfect storm of inspiration, timing, and creative vision—but never say never.

A Timeline of Events for Forrest Gump 2 (Hypothetical Table)

| Year | Possible Plot Point | Relevance |

|---|---|---|

| 2000 | Forrest helps prevent a Y2K bug mishap | Comedy/tech satire |

| 2001 | Forrest unknowingly aids during 9/11 | Emotional anchor |

| 2004 | Forrest Jr. joins a tech startup | Modern economy angle |

| 2008 | Forrest loses money in crash | Financial crisis lens |

| 2016 | Forrest stumbles into political protest | Social justice theme |

| 2020 | Forrest becomes a local pandemic hero | Heartwarming ending |

Why Fans Still Want Forrest Gump 2

The idea of Forrest Gump 2 isn’t just about nostalgia. It’s about closure, continuity, and curiosity. The original movie left people wanting more in the best way. It wasn’t a cliffhanger, but it was open enough to spark imagination.

Fans want to see how Forrest handles the modern world. They want to know if Forrest Jr. grows up with the same good heart. They want another dose of that heartwarming blend of history, humor, and humanity. That’s what made Forrest Gump special, and that’s what could make Forrest Gump 2 unforgettable.

And let’s not forget the soundtrack. The first film’s music was practically a character in itself. A sequel could offer another legendary playlist, taking us from the early 2000s through today with the same nostalgic power.

Expert Opinions and Cultural Impact

Film critics often use Forrest Gump as a benchmark for storytelling, character development, and emotional engagement. It has been studied in film schools and discussed in academic papers. The idea of revisiting this classic in sequel form sparks both excitement and concern.

Some believe it’s best to leave a classic alone. Others argue that if there’s a new story to tell and the right people behind it, why not go for it? As long as the sequel respects the spirit of the original, it could very well become a modern masterpiece.

The cultural relevance of Forrest’s story extends beyond entertainment. The themes of love, loss, perseverance, and destiny are universally relatable. Bringing those themes into a 21st-century setting could amplify their impact for a new generation.

Fan Fiction and DIY Sequels

Given the lack of an official Forrest Gump 2, fans have taken matters into their own hands. There are dozens of fan fictions and short films online imagining what happens next. Some follow the book sequel, while others take wild creative liberties.

These fan projects show just how much the story resonates with people. From animated shorts to full-blown screenplays, fans continue to keep the flame alive. It’s a testament to the lasting legacy of Forrest and a signal that audiences are still deeply connected to the character.

Inspirational Quotes (Real and Imagined for a Sequel)

“Life is like a box of algorithms; you never know what update you’re gonna get.”

“Sometimes, the world don’t make much sense, but that don’t mean you shouldn’t try to make it better.”

“Just ’cause things are different, don’t mean they’re worse. You just gotta find your way.”

“Mama used to say, ‘The future’s just yesterday with better shoes on.'”

FAQs about Forrest Gump 2

Is Forrest Gump 2 officially happening?

No, there is currently no official confirmation of a Forrest Gump 2 in production. There have been rumors and discussions, but nothing has been greenlit.

Was there a book sequel to Forrest Gump?

Yes, the book Gump and Co. by Winston Groom is a sequel to the original novel. It continues Forrest’s story but was never adapted into a film.

Would Tom Hanks return as Forrest?

Tom Hanks has expressed disinterest in reprising the role, citing the film’s original integrity and self-contained story.

Could a sequel work without Tom Hanks?

While difficult, it could work as a story about Forrest Jr. or with creative use of CGI and flashbacks. But many fans believe it wouldn’t feel the same.

What would Forrest Gump 2 be about?

Speculative ideas include Forrest navigating modern events like 9/11, social media, and the pandemic, or focusing on Forrest Jr.’s journey in today’s world.

Why hasn’t a sequel been made?

Creative differences, lack of interest from key players like Tom Hanks, and the risk of tarnishing the original may be factors.

Would fans want a sequel?

Absolutely. Many fans are eager to see Forrest’s next chapter, though there’s also a strong sentiment that the original should be left untouched.

Could Forrest Gump 2 be a TV series instead?

That’s a possibility. A limited series focusing on Forrest Jr. could offer a fresh perspective while paying homage to the original.

Conclusion: The Story That Still Runs in Our Hearts

Whether or not Forrest Gump 2 ever gets made, the fascination surrounding it shows just how deeply the original touched people. The world has changed since Forrest first ran across our screens, but the desire for stories filled with heart, humor, and humanity remains the same.

In the end, maybe Forrest Gump 2 doesn’t need to exist to be meaningful. The idea alone brings people together, inspires creativity, and reminds us of the simple truths Forrest taught us: be kind, stay curious, and always keep running.